KAIVANYA EXTRUSION TECHNIK

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to KAIVANYA EXTRUSION TECHNIK

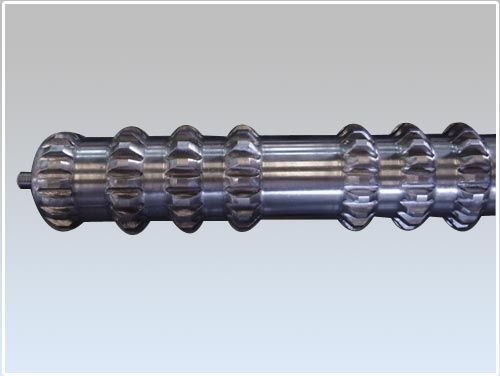

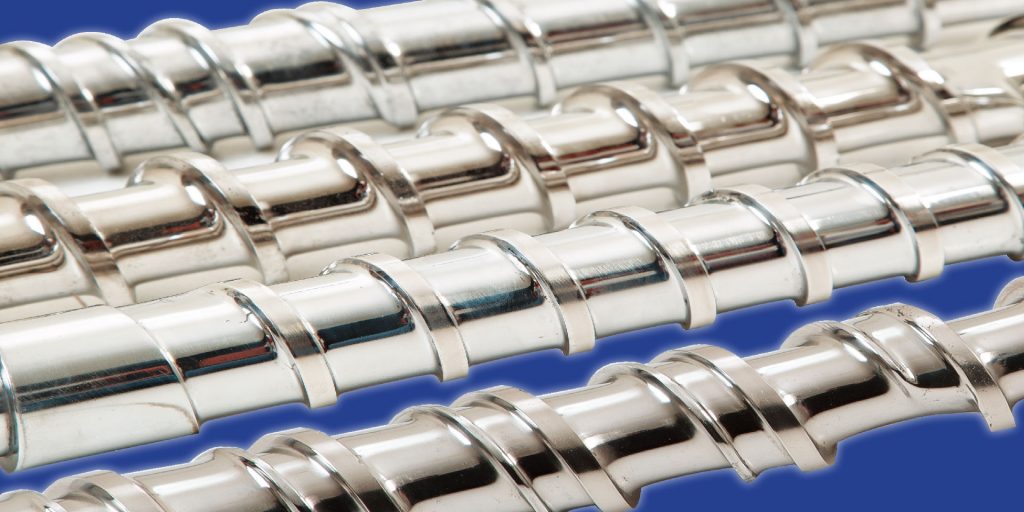

Bimetallic Barrel

Barrel from Dia. 25 mm to 200 mm & Length upto 6000mm

Barrels processed with bimetallic alloy hardface coating have many virtues, such as high hardness, stronger wear & corrosion resistance. Its general properties are three to fifteen times more compared to the nitriding steel. They are wildly used for highly abrasive & corrosive materials like engineering polymers and pvc compounds. The main machining methods are as follows: spot spray, spray coating, cover coating, mould, butt welding etc. The bimetallic process used in world as advanced technology for better life with consistent production and quality. It is the best choice forproduction special screws. Polymers can be used : Minerals, Glassfibers, Pigment, Carbon fibers

CPM/Specialized tool steel vacuum hardened Barrels

Spin cast boron composite inlay layer Barrel (1.5-2mm)

Spin cast (upto 35%) Tungsten composite inlay layer Barrel

PM Tool Sleeve and liners (CPM 9V)

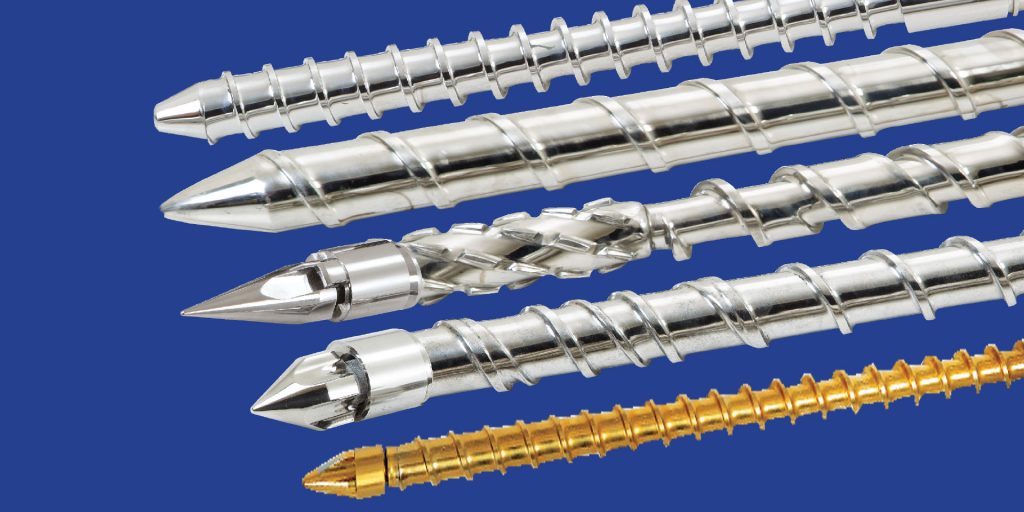

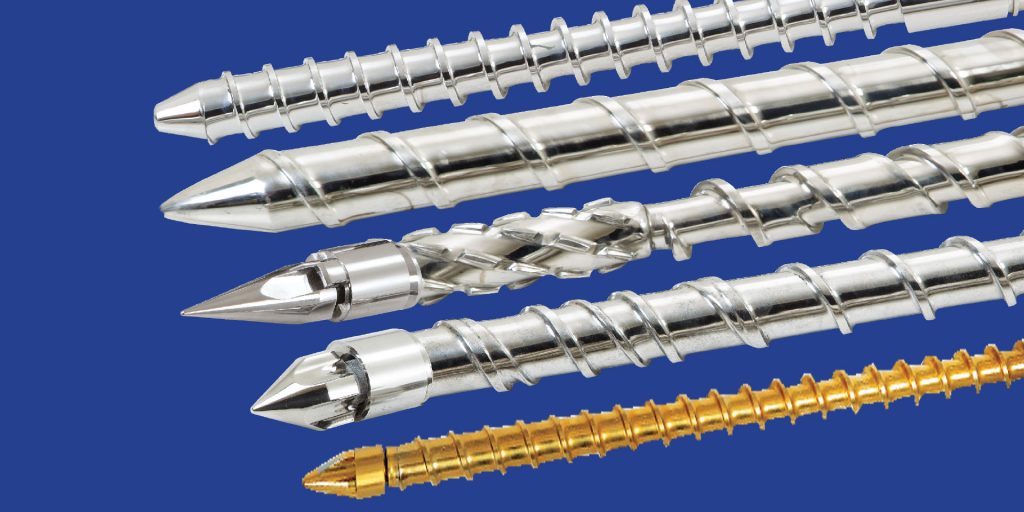

Injection Screws

Screw from Dia. 25 mm to 200 mm & Length upto 6000mm

BASE MATERIAL: Screws are made from nitroalloy steel (AISI 4340 NITRALLOY 135M), stainless steel (304, 316, 416, 17-4ph), Tool steel & CPM tool steel.

Universal screw

Applied with Highly glass-filled materials, Materials with metallic powders or mica fillers & Shear-sensitive polymers.

universal screw with a mixer

Applied with Molding materials with color and additive concentrates, fiber reinforcements, thermoplastics & engineering resins.

Barrier melt – pro screw with a mixer

Applied with any polymer except rigid PVC.

Double barrier melt – pro screw with a mixer

Applied with Molding materials with color and additive concentrates, fiber reinforcements, thermoplastics & engineering resins.

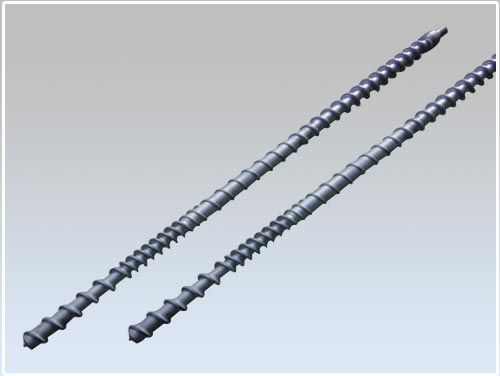

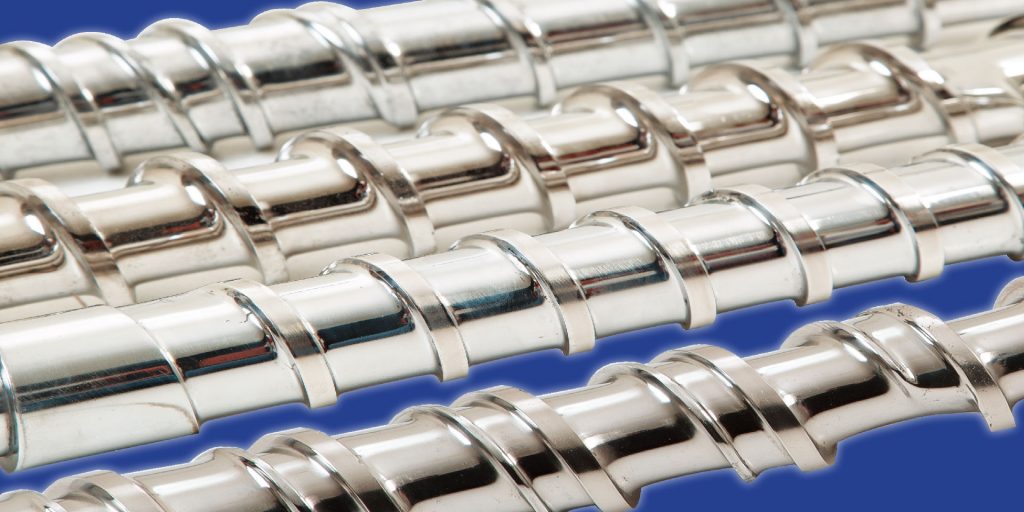

Extrusion Screws

Screw from Dia. 25 mm to 200 mm & Length upto 6000mm

BASE MATERIAL: Screws are made from nitroalloy steel (AISI 4340 NITRALLOY 135M), stainless steel (304, 316, 416, 17-4ph), Tool steel & CPM tool steel.

HARDENING & HEAT TREATMENT: Toughening, Tempering, Gas/Ion Nitriding& Additional Bimetallic Coatings can be incorporated. We also do special surface treatment like hard nickel plating, chrome plating & PVD coatings, HVOF Thermalspray & PTA weld overlay, vacuum through hardend screws.

High productive smooth barrier meltpro screw with a mixer This barrier screw has proven its value in more than 30 years of field experience.

High productive groovefed barrier meltpro screw with a mixer Open & closed barrier melt & solid seperated channels based designs screws delivers higher throughput at lower melt temperatures at higher melting efficiency. Has proven its benefits in processing polyolefins, PET, ABS and PLA in various extrusion & blow molding processes.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.